1. Has applied for and been granted a number of patents for inventions;

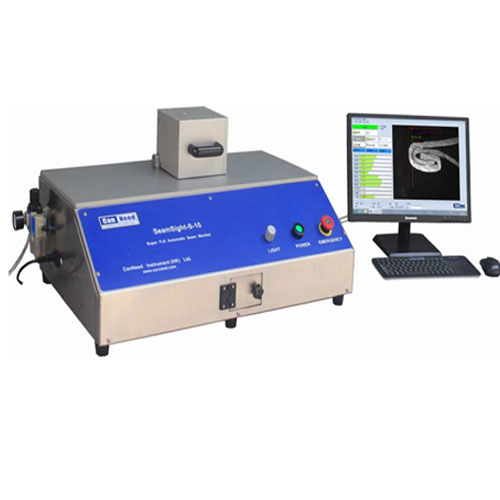

2. Innovative invention of automatic can cutting and measurement seam monitor to replace the old manual can cutting measurement;

Innovative design enables the gauge to perform measurements on seam with minimal effort or operator intervention. The operator only needs to put in and take out the empty can samples.

4. Extreme safety and avoids the risk of injury resulted from manual can cutting;

5. High efficiency and auto finishing the whole measurement process;

6. Low noise;

7. High precision, clear display, equipped with the advanced Golden Lens® video capture device;

8. Repeatable and accurate measurement, adopting the auto cutting method to ensure a clear-cut cross-section without deformation or burrs;

9. Simple, easy-to-use operation;

10. Stable performance and the seam saw made of hard metal alloy is durable;

11. Easy maintenance, drawer type cleaning of iron chippings and shavings, minimal care and maintenance;

12. The client chooses the proper can type along with the order, and chooses one from the following can types:113, 202, 206, 209;

13. Chuck number correlation of test data.

• Resolution 0.001mm, Precision 0.005mm

• Magnification factor: 60 ×, Line

• positioning magnification factor: 180 ×.

Features:

1) Automatic can cutting and measurement, efficient and accurate;

2) Equipped with Golden Lens® video capture device which interference-free of external light source and ensured the high image definition;

3) SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink);

4) There are 5 calculation formulae of Overlap Rate for clients to choose;

5) Resolution: 0.001mm, Precision: 0.005 mm, Magnification factor: 60 ×, Line positioning magnification factor: 180 ×;

6) Magnifier option enable users to magnify the testing image for a more accurate line positioning

7) The Anti-noise Seam Saw can be chosen, help protect your hearing;

8) Report format can be customized, flexible for different report styles of different companies;

9) 12 Measuring Items: Tightness, Seam Length, Body Hook Length, End Hook Length, Overlap, Seam gap, Overlap rate, Body Hook lapping rate, End Hook lapping rate, On-screen Seam Thickness; Length of Tightness; Actual Seam Thickness; Actual countersink;

10) Software adopted data base management system, measurement results and images saved in the data base;

11) Users can review or re-measure the saved projects at any time;

12) Graph chart statistic function, automatically analyze and compare the measurement results;

13) Data can be exported as an Excel file;

14) Predefine various qualification standards, auto judge and warn whether the results are qualified in every measure;

15) Measurement results and label lines mark directly on the image, results will also display in corresponding field on the screen;

16) Seam image can be printed, stored, no need to retain the sample cans;

17) Provide with calibration piece, calibrate at any time;

18) Use the monochromatic source, make it much more durable.